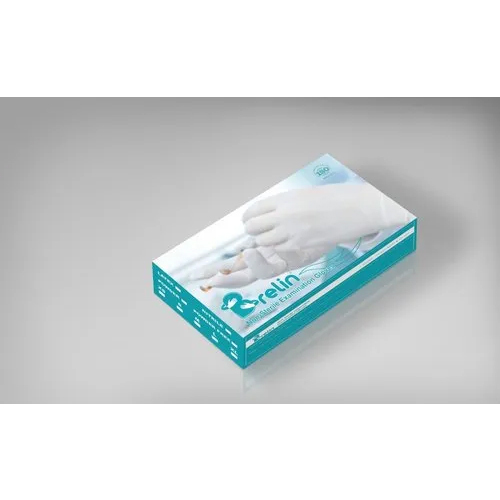

Food Processing Gloves

163.18 INR/Box

Product Details:

- Material Nitrile

- Grade Cleaning Industrial Food Medical

- Powdered No

- Size XS M L XL

- Compression Ratio 600

- Color White

- Disposable No

- Click to View more

X

Food Processing Gloves Price And Quantity

- 163.18 INR/Box

- 600 Box

Food Processing Gloves Product Specifications

- 3.5 Gram (g)

- Cleaning Industrial Food Medical

- No

- 600

- No

- No

- White

- Nitrile

- XS M L XL

- Medical

- No

Food Processing Gloves Trade Information

- 10000000 Box Per Month

- 7 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

Product Description

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Gloves' category

We are mainly dealing in bulk quantity.

|

PHOENIX MEDICAL TECHNOLOGIES AND IMPORTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free